QUALITY MANAGEMENT

We plan, organize and constantly control the quality of our work processes, products and services in the long term for the best possible result.

Certification

In order to be able to offer our customers consistent quality at all times, we have defined our workflows in processes. These are checked by external service providers in certification and monitoring audits.

Our company has been certified according to the DIN EN ISO 9001 ff series of standards without interruption since the year 2000.

FIRST PART SAMPLING

At the customer’s request, we carry out initial sampling using the company’s own forms based on VDA Volume 2. If desired, we also carry out initial sampling on forms provided by the customer.

In doing so, we continuously monitor the current status of the sampling in order to only allow approved components to flow into series production.

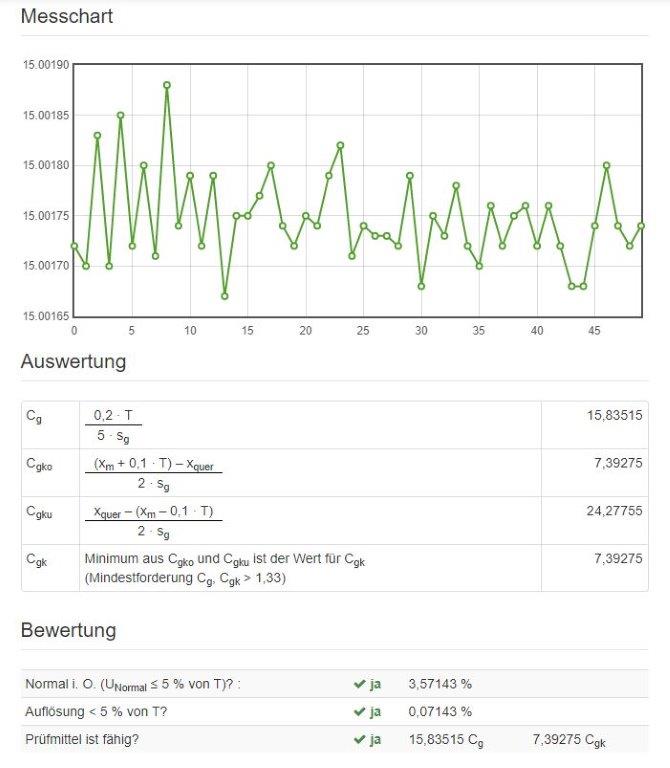

Measuring system analysis / Test equipment capability analysis

A measurement system analysis is carried out cyclically on the complex test systems in the company according to MSA procedure 1.

This ensures that all testing tasks in the company can be carried out in a traceable manner and that the results obtained can be made available to our customers at any time in a reliable manner.

RISK ASSESSMENT

For new parts, an internal risk assessment of the manufacturing feasibility of your requested components is carried out as standard, so that possible error influences are already identified and eliminated in the planning phase.

The result of this assessment is a clear feasibility status for processing your order.

System-guided test equipment management

In order to obtain consistently correct and traceable test results, our complete pool of measuring equipment is monitored at cyclical intervals. The determined characteristic data of the measuring and test equipment monitoring can be made available to our customers at any time.

system-based process management

Due to our self-developed process management system, we are able to detect and document changes in the production processes at any time.

Furthermore, we can provide our customers with information about the production status, planned changes or feedback requiring approval at any time.

Auditing

To keep an eye on our corporate processes, we have an IT-based audit system. With this system, all data of the described processes are determined in internal audits and used for evaluation.

Our customers also like to use the opportunity of a customer visit or a customer audit to get to know our company processes and to gain an insight into the consistency of our company specifications.

Do you need more information or would you like a quote for the production of components?

Then arrange a meeting with us now.