The

Company

As a medium -sized company with over 30 years of experience in cutting technology, we support you with professional and economic production of components of all kinds.

Company

History

The history of Kögel GmbH

Tour

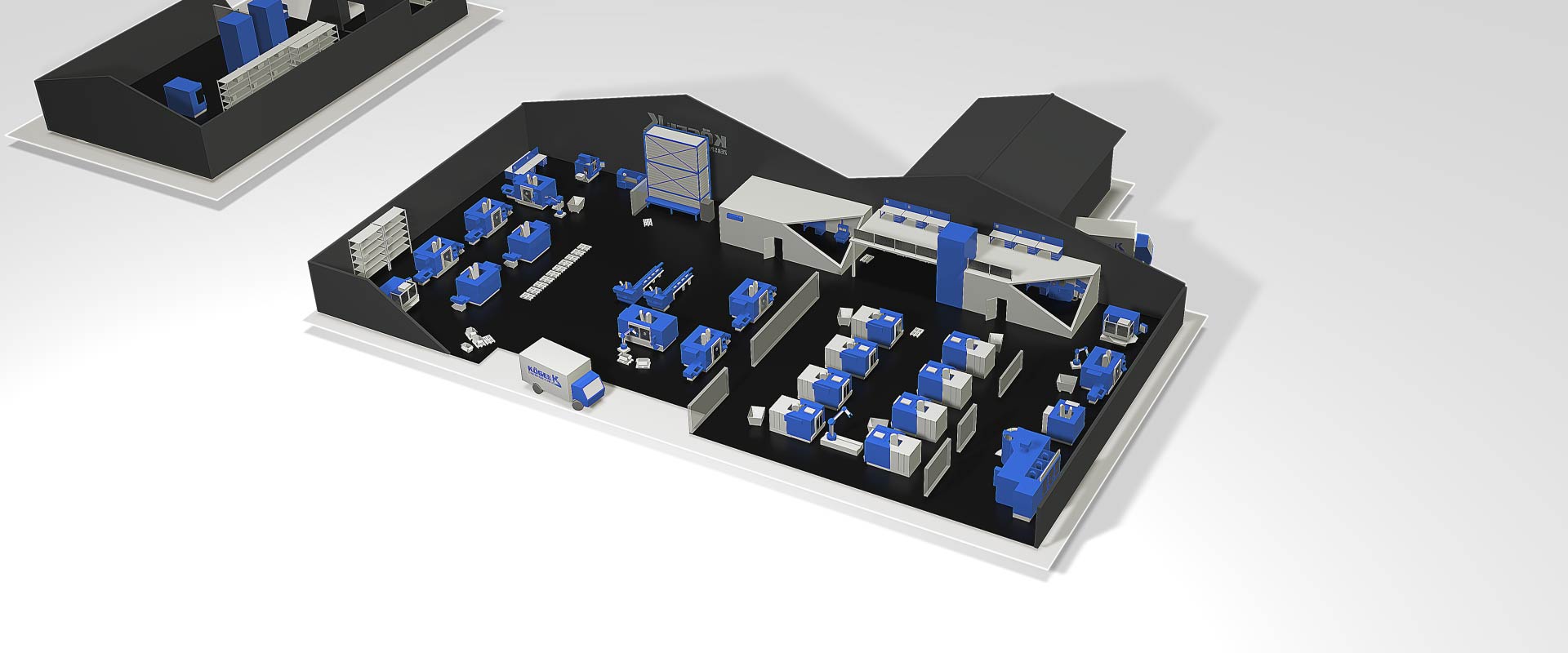

Our production facility interacted

Our corporate policy

Click on the individual areas: Vision – Values – Mission

Our customers are driving innovations, which is why they also need a partner who works innovatively.

As one of the leading cutting companies, we are at the side of our customers as a competent partner to support them in their requirements. With the most modern manufacturing techniques, we are always at the state of technology to be able to offer our customers the best quality at the best price. Top trained and motivated employees can organize and design their own workplace independently. Consistency and stability give us the trust of employees, customers and suppliers.

Our customers produce high-tech products, which is why they also need a partner who supplies them with high-tech components.

We offer the customer from a single source from component planning to pre -assembly to the customer to support him in his strategy. We offer our customer a maximum of service, quality and support so that he can also offer this to its partners. We always try to exceed the goals and requirements of our customers.

Our obligation towards our customers, colleagues and our environment.

We are looking for solutions and not the problems. We support our customers to become more successful, because only then we are successful. We are only successful as a team. That is why we appreciate and respect each other. We are continuously developing professionally and personally in order to be able to be powerful and successful in the future. We regularly question our processes so as not to become blind. Ecological awareness and the economical handling of resources protect our highest asset, nature.

Vision

Mission

Values

The history of Kögel GmbH

The year was still dominated by Corona, but presented the economy with new challenges. On the one hand, the strong increase in demand from our customers is being met by an increasing shortage of raw materials. In conjunction with massive increases in the energy sector, material prices climbed to a record high!

The constant expansion of our production capacities also required a Restructuring of the 4-axis group. Here we have implemented a new hall layout for optimization and thus realized the following investments.

1x Heller HF3500 5-axis machining center with automated loading system

1x Heller H4000 4-axis machining center with automated loading system

1x Heller H2000 4 axis machining center

1x STS Rz50 loading robot cell

SARS CoV2, better known as the Corona virus, turns the world upside down. The pandemic leads to the partial shutdown of workplaces, collapse of supplier chains, short-time work as well as sending Germany and the rest of the world into a global economic crisis.

Due to our customer structure and the related classification as a systemically important company, we were able to survive this period with relatively little impact.

In spite of this, we stuck to our restructuring plans. Due to the newly created space from the relocation of the deburring/shipping departments to the neighboring building, a hall layout was designed based on the planned investments. The milling/turning department moved to our Hall 2, creating space for expansions to our 4-axis horizontal department.

For our cleaning after TEM deburring, we exchanged our Sporer MPC for an LPW PowerJet CnP. Here, the focus is on removing the aluminum oxide that has formed and on Fine cleaning of the components. The CnP process is particularly suitable for cleaning deep bores. An expansion of the QA facilities was also carried out.

In order to be prepared for increasing demand in the future, we rented an area of another 1000 square meters in the neighboring building. The downstream production processes deburring/cleaning/shipping were relocated there, and so we gained space for additional machines in the existing production halls.

In this move, our previous PERO V1 cleaning system was also replaced with a new PERO R1.

Foundation of the company Michael Kögel Fräs- und Bohrtechnik on January 1, 1989.

In the center of Schwabsoien the foundation stone for the future production of precision parts is laid with 2 machines and 3 employees.

Start Of Assembly of shock and vibration dampers for the company Leben & Co.

After only 4 years the Expansion of the production area creates capacity for new manufacturing possibilities.

Start Of Training for the mechanical engineering technician:

Since then, Kögel has continuously trained young people to become qualified specialists.

Move into the New Company Building in the industrial park of Schwabsoien. The company presents itself on 600 sqm production area, as well as with 180 sqm area for offices and administration in a new appearance.

In this process the shock absorber assembly was split off again to the company Leben & Co.

Quality As A Guiding Principle: We certify ourselves for quality management according to ISO 9001!

The growth and the upswing require a renewed Expansion of the production area by another 200 sqm.

In close contact with the machine manufacturer Stama, we are one of the first suppliers to develop Fully Automated 5-axis Milling-Turning Combination Processing as a new manufacturing concept.

In addition to the technical professions, we now also offer Training as an Office Administrator.

Another Extension provides the necessary space to expand machine capacities and restructure production throughputs.

We now produce on an area of 2000 sqm with a team of 52 employees.

Global Economic Crisis: The crisis is also having a full impact on us and our customers. Only by opening up new areas of business and optimizing internal processes can we master the crisis and see ourselves well positioned for the future.

An additional fully automatic machine complements our machine park. Another Milling-Turning-Machining Center based on the Stama 526MT is now available. With a fully-fledged counter spindle and 7-axes, opening up additional manufacturing possibilities for our customers!

Introduction of the new Tool Management and CAM system. Replacing the old system, Kögel continues to focus on optimizing the processes before the actual production. Using CAM programming to get to the usable CNC program even faster - Stocking the tools in the fully automatic storage system - Measuring the tools with a CNC-controlled tool presetter - Shrinking and balancing the tool for even more precision.

Extension of the machine park by

2x Heller H2000 with U-axis. This investment does not only mean an increase in capacity! The integrated U-axis opens up new production possibilities which, for example, make pre-machining in the form of pre-turning unnecessary. This saves unnecessary transport routes and handling of the goods and increases the quality of the overall component.

Our production facility interacted