Our services - from

manufacturing to assembly

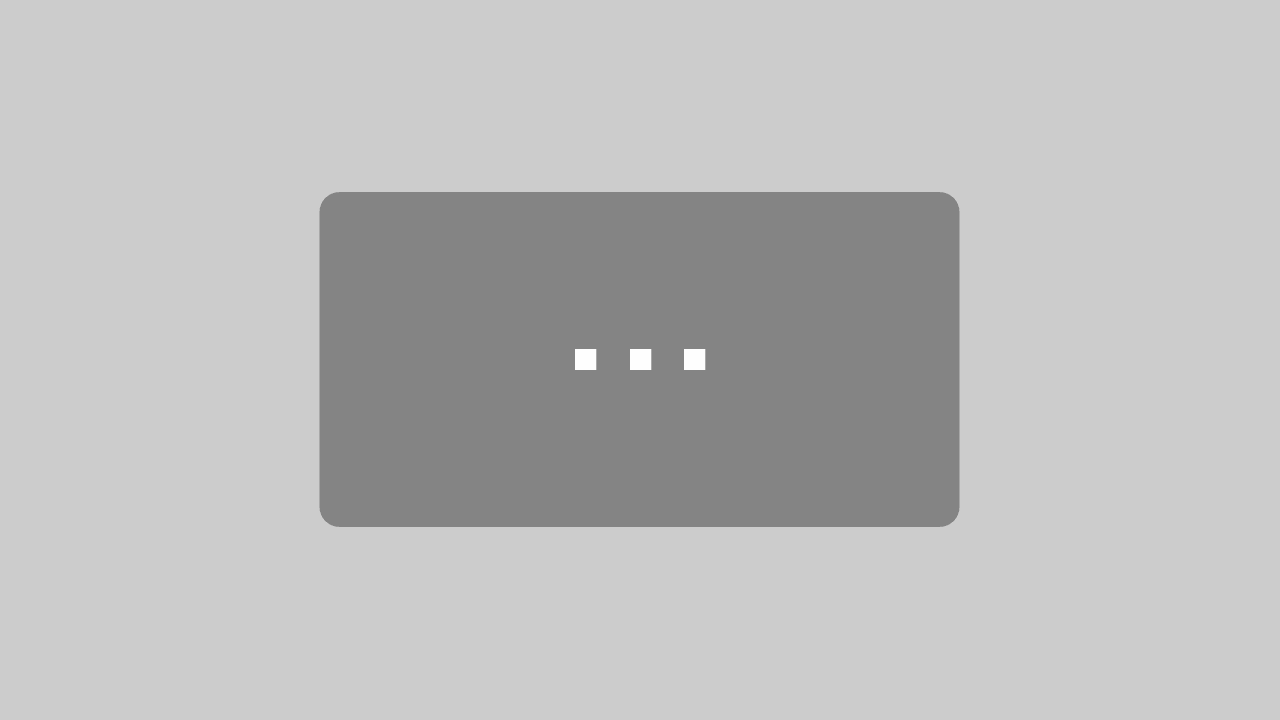

Control blocks, valve housings, cylinder tubes – we mainly produce CNC milled parts as well as components from turning and milling combinations for different industries.

For this purpose, we procure the prescribed raw materials and create the programs for our machining centers on the basis of your production drawings.

CNC manufacturing:

Economical and efficient

Machining takes place on modern CNC production machines in up to five axes. This ensures that we always keep an eye on profitability for each and every one of your milled parts.

All our tools are recorded in a database. The digital replication of our machines with specific peripherals enables us to fully simulate the program sequence on the PC. This allows a fast and optimized implementation with the finely balanced and laser-measured tools.

By loading the video, you accept YouTube's privacy policy.

Learn more

CNC CUTTING

Specialized in milling, as well as turning-milling combination machining in full automation, we primarily produce components from the following materials:

various aluminum alloys

structural steels

free-cutting steels

various plastics

brass

simpler machining in stainless steel

We are at your disposal as a partner from the prototype over the 0-series up to the small/medium series (depending on the processing volume up to approx. 10.000 pcs./year).

The resulting temperatures of 2500 to 3500 °C initiate the combustion of the burr with the remaining oxygen.

Thermal deburring: In-house possible

We are the specialists for removing unwanted burrs. As one of the few companies for machining technology, we offer thermal deburring in-house. In addition to conventional deburring methods, we remove the finest residual burrs with our ATL iTEM250. In this way, we avoid process-safe detachable particles and protect your system from unplanned downtime.

Cleaning your components is also an integral part of our process chain. If you have special requirements for residual contamination, let us know.

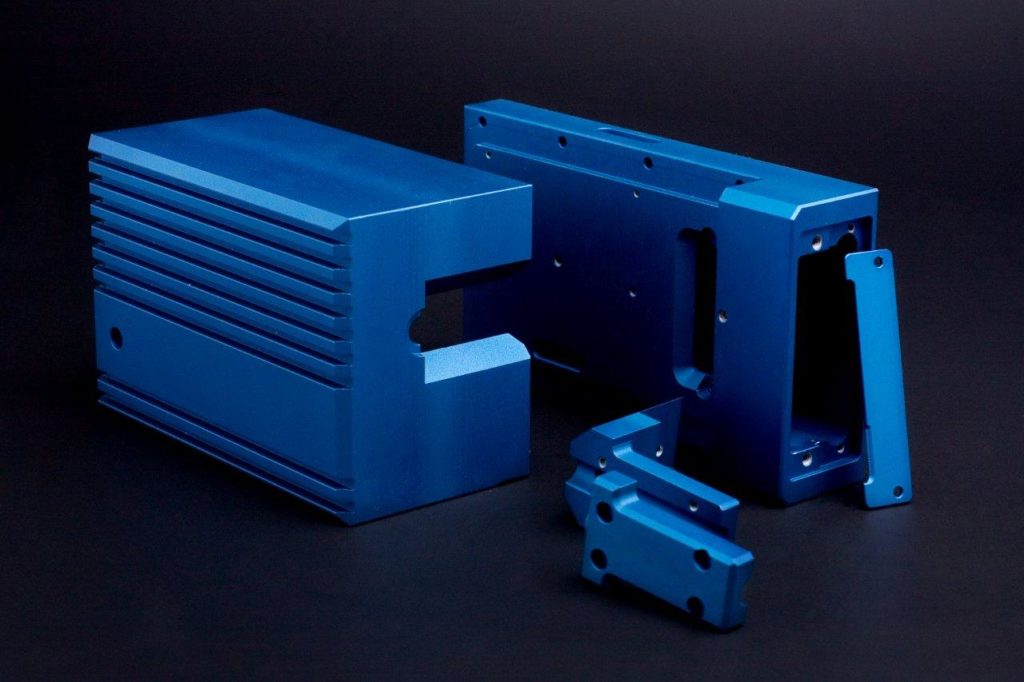

Surface finishing: Effective protection

After production, you can have your components refined. In cooperation with our partners, we offer you a wide range of options. Anodizing, chromating, passivating, burnishing, painting – the choice is yours.

ANODIZING YOUR ALUMINUM COMPONENTS

The anodizing process (abbreviation for electrolytic oxidation of aluminum) is a surface engineering method for creating an oxidic protective layer on aluminum. In contrast to galvanic coating processes, an oxide or hydroxide is formed by converting the uppermost metal zone. The result is an approx. 5-30 micrometer thin layer (depending on the alloy used) that protects against corrosion.

The color varies from light to dark silver-gray. Through additional interspersion of color pigments, it is also possible to realize other colors, such as black, anthracite, red, blue or gold.

CORROSION PROTECTION OF STEEL COMPONENTS

In order to protect your steel components permanently against corrosion, various options are available. Frequently, the parts are coated with zinc by electrolytic means. Additional passivation can further increase the protection, and a decoratively attractive surface is achieved which appears either slightly bluish (Cr6-free) or yellow iridescent (Cr6-containing). However, due to environmental as well as health aspects, Cr6-containing coatings are declining, so that in the medium term they will be replaced by the ever-improving Cr6-free treatments.

Other alternatives include nickel plating, burnishing (only short-term corrosion protection) or conventional priming/painting.

Assembly:

Ready-to-install units

We are happy to support you with your assembly work. Let us assemble your components into complete units. For this purpose, we take over the C-parts management for you and procure all required standard parts such as screws and fasteners. This shortens your procurement times and frees up your capacities.

Industries and components (selection):

Especially for these industries, we manufacture components made of aluminum alloys or steel:

- Hydraulics: control block, housing, block, valve housing, flange, pump flange, bellhousing, intermediate plate, valve carrier, accumulator block, interlinking block, connection block, equipment carrier, reversing block

- Pneumatics: manifold block, P-bar, connection block, pneumatic housing, valve housing, cylinder tube, cylinder cover, pneumatic block, inlet chamber, air distributor

- Electrical engineering: electronics housing, circuit board housing, heat sink, transmitter housing, receiver housing, antenna support

- Mechanical engineering: bearing, trestle, cover, holder, plate, adapter, bracket, insert nut, lever, retaining block, locking device, clamping holder, strip, spacer, hold-down device

- Medical technology: actuating block, foot pump housing, cylinder block, cylinder lock, output block, distributor block

- Automation technology: gripper, swivel arm

- Drive technology: driver, cover, base, plate, guide, guide carriage, wiper

- Laser technology: laser housing, housing cover, plate, base, mirror holder, lens holder, side wall

- Painting technology: piston housing, gun body, mixing block

This is what you can expect from

Kögel GmbH Zerspanungstechnik:

Service

We attach great importance to good service. As a family business, we maintain intensive contact with our customers. We are always available for you and clarify open questions at short notice. If you need an offer from us, you can expect it in the shortest possible time – if possible, even within one day.

Quality

Outstanding quality is the be-all and end-all in the production of sensitive and complex components. That is why our quality assurance department has the best technical equipment. Regular inspections are an integral part of the entire production process. Networked tablets on the machines and software developed in-house document all relevant test steps and make them accessible via the QA control station – so that the quality of your components is right in the end.

Delivery reliability

We are proud of our high delivery reliability. This is regularly confirmed by the quality management of our customers. We deliver your components punctually on the promised date. We react to possible delays within the process chain in good time so that there is no delay in delivery for you.

Do you need more information or would you like a quotation for the production of components?

Then arrange a meeting with us now.